Advanced Planning and Scheduling (APS)

Which system is best suited to the characteristics of my supply chain?

What is APS?

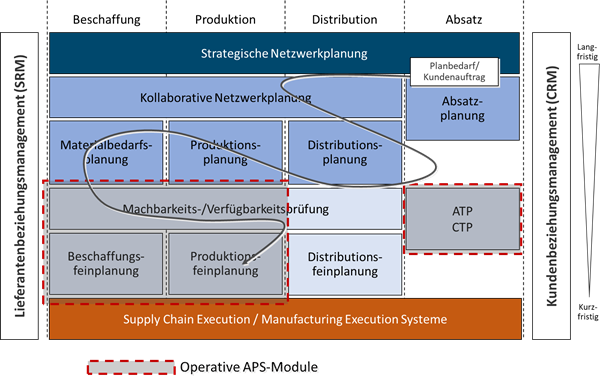

The term Advanced Planning System or Advanced Planning and Scheduling (APS) generally refers to software systems that use modern planning models and IT processes to support planners in solving planning and decision-making problems in production and logistics, particularly in supply chain management (SCM).

APS systems aim to eliminate the weak points of ERP systems. This is achieved through closer integration of the planning modules, a coherent planning hierarchy from strategic to operational planning, more precise modeling of restrictions (bottlenecks) in the supply chain and the use of the latest IT methods, e.g. completely memory-based planning models.

Communication with the subordinate enterprise resource planning systems (ERP) is currently generally carried out via interfaces, i.e. the APS takes the necessary data from the ERP, carries out simulations and optimizations and passes the results back to the ERP. Compared to ERP systems, APS solutions are characterized by a significantly higher computing speed, including real-time processing of new or changed data.

APS in the narrower sense describes the software systems for the operational planning and control of the supply chain, i.e. starting with the feasibility check of new primary requirements (planned requirements or customer orders), through material requirements planning, production planning and purchased parts planning, to fine production control and sequence optimization.

Figure 1: Supply chain management matrix: APS systems form the information technology basis for modern supply chain management (SCM)

WHAT DISTINGUISHES APS FROM TRADITIONAL ERP SYSTEMS?

ERP and PPC systems based on MRPII logic carry out backward scheduling of the various process steps against unlimited resources (capacities, material) based on the primary requirement dates. This can result in scheduling into the past (backlog) or unfeasible plans due to capacity bottlenecks when scheduling new independent requirements.

In some ERP systems, attempts are therefore made to avoid backlogs by setting a frozen zone or to reschedule backlogged planning elements by forward scheduling. However, as this is only done locally for the planning elements concerned, the synchronization of the collective orders, i.e. the linking of requirements and requirements coverages across all production levels, is inevitably destroyed.

You can download the complete white paper using the download button below.

Download whitepaper (Only available in German)

Author

Managing Partner

REDPOINT.TESEON GmbH