OpEx – Operational Excellence

Operational excellence describes a company’s ability to carry out value-adding core processes efficiently and effectively. This is achieved by consistently thinking from the customer’s perspective in order to continuously optimize its added value and thereby gain a sustainable competitive advantage. The people involved have a range of tools, instruments and procedures at their disposal, which typically originate from the areas of lean management, six sigma or agile organization. In practice, terms such as process excellence, management excellence or operations management are often used synonymously with operational excellence. However, despite the different variations, at its core it is always about eliminating waste, reducing operational costs and risks and creating added value for the customer.

Identify the critical success factors for your company. Build sustainable competitive advantages through excellent processes and structures.

Focus on your core processes, eliminate waste and optimize value-adding and supporting activities for maximum customer benefit.

Increase your product quality in a targeted manner by optimizing processes and focusing on the relevant product properties.

Operational excellence – leveraging potential

Operational excellence (OpEx) is the continuous effort of a company to optimize its processes and systems on an ongoing basis. This essentially involves pursuing three goals:

- Increasing Productivity

- Increasing Customer Benefits and Quality as well as

- Reducing Costs

The basis for the successful implementation of OpEx in the company are clear objectives (top targets), which are typically derived from the corporate strategy. The top targets are broken down and operationalized by means of target cascading to the various organizational units and/or processes. Systematic and continuous improvement is achieved by regularly reviewing the key figures determined in conjunction with suitable visualization and management tools, e.g. store floor management.

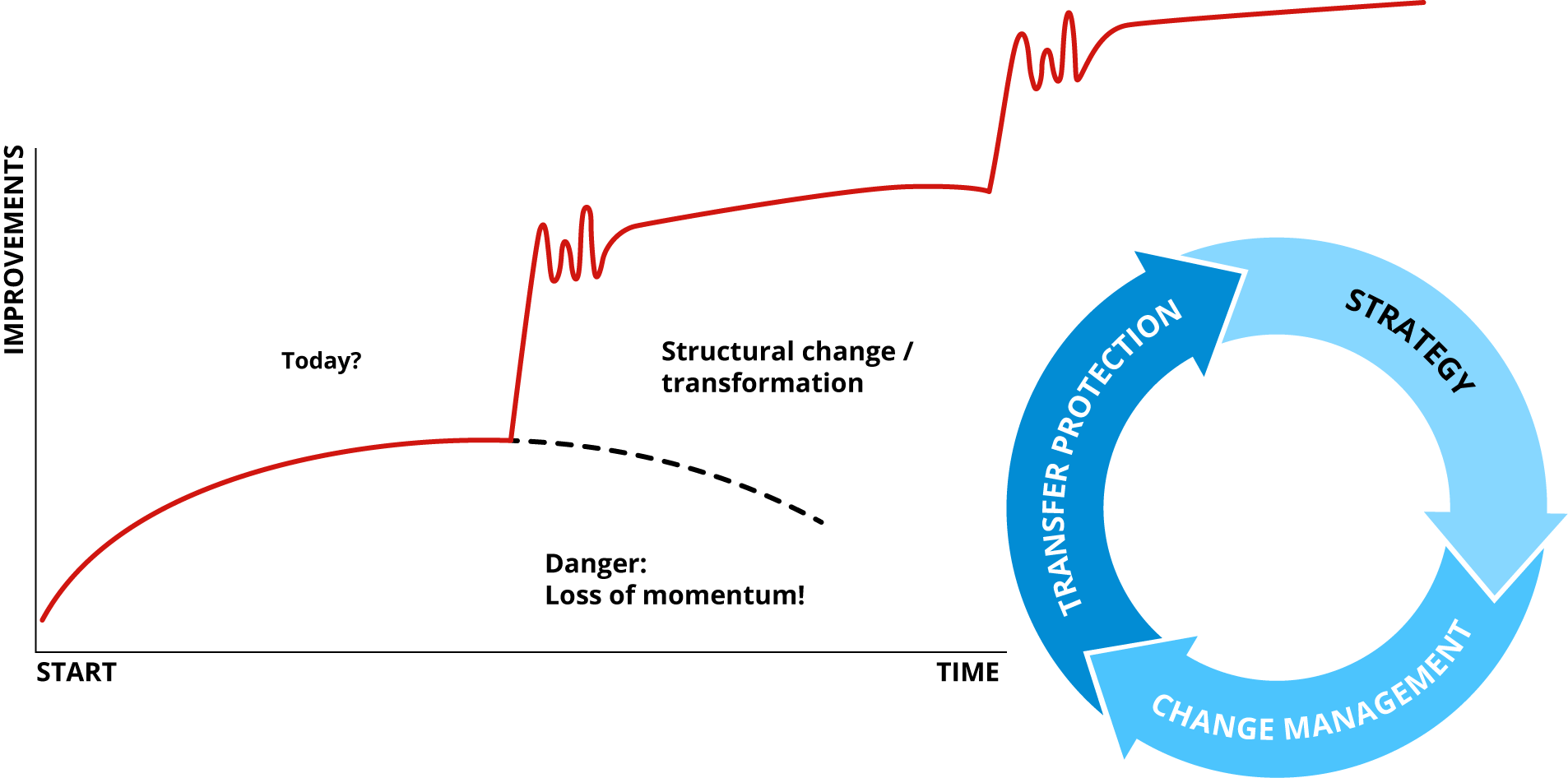

The consistent pursuit of OpEx is not a short-term project to quickly leverage potential. Rather, it should be seen as a long-term, value-adding initiative that requires staying power. The tools, methods and procedures used in OpEx projects include, for example:

- Six Sigma

- Lean Management

- Agile Working Methods

- Kaizen

- Process Performance Management (PPM)

Typical assignments for our customers are, for example:

- Development of a coordinated management system that involves all managers and employees in a systematic process of target cascading based on the company’s objectives

- Establishment of effective store floor management

- Increased productivity through the targeted use of robotics in the production area

- Introduction of CIP to eliminate waste in the production area

- Increase of efficiency in indirect areas through office excellence with more efficient self-organization, standardization at the workplace, improvement of meeting and communication structures, process optimization and structured problem solving

Our EXPERTISE ALONG THE VALUE CHAIN WITH SUPPLY CHAIN MANAGEMENT

On the basis of numerous projects on this topic, redpoint.teseon has built up comprehensive know-how that covers all aspects of operational excellence, including industry-specific issues. With the help of our project management experience and our method toolbox, we are able to develop your management and business processes in a short space of time and increase the efficiency of your processes.

Achieve your cost, quality and time targets with us!

Numerous renowned customers confirm the high quality of our services – guaranteeing you the security of your investment. Use your full potential for your success. Ultimately, it’s the people who make the difference.

Get in touch with us! Our aim is to design and optimize your business processes so that they are implemented and lived efficiently – together with you and in collaboration with customers, suppliers and network partners.