Integrated Business Planning & S&OP

The holistic and efficient coordination of increasingly complex global value chains continues to offer most companies considerable potential for savings, especially in high-wage countries, and is a key success factor for a company’s long-term competitiveness. The flow of goods, merchandise and information within the supply chain must be optimally adjusted and synchronized in order to meet customer needs and ensure cost efficiency.

Especially in times of volatile environmental conditions in the “VUCA world” (volatility, uncertainty, complexity, ambiguity), the relevance of flexible and efficient planning processes that ensure customer satisfaction from strategic planning to detailed operational planning is increasing.

- Planning & Control

- Management & Supervision

- Work Ethic

- Qualification

- IT

- Other

Causes of Efficiency Losses in Production

Source: International Productivity Study “The Proudfoot Report”

Increasing customer satisfaction due to greater reliability and informative value of the supply chain, as well as more flexibility with regard to customer requirements.

A service class concept geared towards market requirements leads to optimum product availability and delivery times in line with market requirements.

Optimized planning processes reduce the amount of capital tied up in inventories and, in addition to the reduced planning effort, lead to a balanced utilization of resources.

The holistic approach to supply chain planning

The central aim of supply chain planning is to identify market requirements at an early stage and take targeted measures to meet them. The increasing differentiation of products and services has led to new challenges for supply chain planning. Increasing variant diversity, shorter product life cycles or the establishment of direct sales channels result in decreasing predictability of sales. Furthermore, on the production and procurement side, the effects of longer global supply chains, the distribution of production across several plants or lower inventory levels must be taken into account in the overall planning. In particular, the mixing of stocked products (make-to-stock), order-related assembly (assemble-to-order) and order-related production (make-to-order) increases the complexity of the planning processes. This requires a holistic planning approach that integrates planning activities in the strategic, tactical (“sales & operations planning”) and operational horizons, as well as linking sales, inventory, production and procurement planning.

Supply chain planning focuses on coordinated, feasible and consistent planning between all parties involved. Particularly at the level of strategic planning and sales & operations planning, attention must be paid to the possibilities for top management to exert influence in order to achieve targeted planning. Supply chain planning therefore makes a direct contribution to the competitiveness of your company.

In a holistic approach to supply chain planning, both the design of the structural and process organization as well as the appropriate methodological approach and optimal support from IT and planning systems must be considered. Trends in digitalization and AI offer the opportunity to significantly increase the quality of planning while reducing the effort involved.

“Optimally” planning and controlling supply chains – but how?

In the course of strategic planning, sales volumes are initially planned for a multi-year planning horizon, taking into account product life cycles, the development of new markets or economic cycles. Decisions on the necessary internal resources or capacities on the procurement market are derived from this. Strategic sales planning is aggregated at the level of suitably grouped product groups. When launching new products, the order decoupling point and the stock levels in the production and distribution network are also determined at this stage. The projected sales volumes also serve as the basis for adjustments to the supply chain design with regard to the necessary production capacities, locations and distribution structure. Strategic procurement planning makes strategic make-or-buy decisions on the basis of sales planning and derives a suitable procurement strategy. By linking strategic planning with the product creation process, planning restrictions can be positively influenced with regard to lead times in production or necessary inventories.

Central Element – Sales & Operations Planning (S&OP)

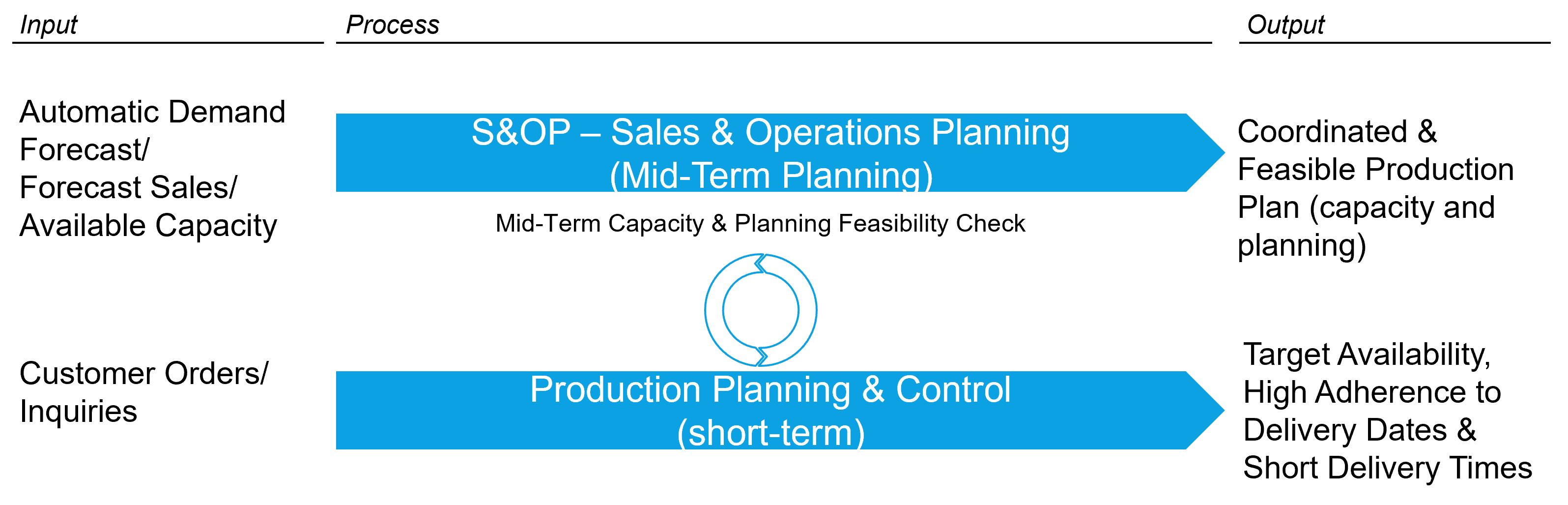

Sales & operations planning creates detailed planning for the medium-term horizon as part of a continuous process. Particular attention must be paid to reconciling competing business objectives such as target availability, delivery times and inventory levels. The basis for sales & operations planning is sales planning, which depicts the sales volume expectations for the defined planning horizon. The subsequent review of the sales plan for capacity and planning feasibility is the core of sales & operations planning. In the capacity feasibility check, either measures are implemented to adjust the available capacity to the planned sales volumes or a reduction in the sales plan is agreed with the sales department, the so-called constrained forecast. The demand & supply matching measures are based on the defined corporate goals. It is advisable to carry out the entire S&OP process with an interdisciplinary team between supply chain management, sales, production, purchasing and logistics and in accordance with a planning calendar.

The specific design of the S&OP process depends on customer requirements, product characteristics and features of the production process. In industries with a highly seasonal demand pattern, for example, pre-production or inventory build-up can be controlled via sales & operations planning.

A large number of IT systems are available to prepare the information required for sales and operations planning and to support planning decisions. Methods from the field of artificial intelligence and optimization methods can also be used to support planners in the preparation of sales planning and capacity planning.

Operationalization of S&OP in the context of production planning & control

Sales & operations planning is only fully effective when it is operationalized in the course of operational planning. The results of sales & operations planning set the framework for operational planning or order processing. Either the forecasted quantities from the medium-term sales plan are used to identify deviations in incoming orders (and therefore also in the required capacities) at an early stage. If necessary, a detailed sales plan is created for the short-term area at the individual item level or the medium-term plan is revised using demand sensing methods. The demand information thus created is then used as the basis for production planning and control, as well as transportation and distribution planning.

Our EXPERTISE in the field of supply chain planning

Based on the successful implementation of numerous SCM projects in complex corporate situations, redpoint.teseon has been able to develop an outstanding and holistic know-how in the field of supply chain planning. Our methodical approach in both the analysis and implementation phases is pragmatic, goal-oriented and leads to sustainable success.

Our approach encompasses the entire value chain: the aim is to harmonize market requirements (demand) and the satisfaction of demand (supply) in the best possible way across all areas involved, i.e. sales, development, production, procurement, logistics, etc.

Our belief: The business effects can only be achieved through a reasonably complex interplay of organizational structure, processes, clear roles and responsibilities, the “Supply Chain Operating Model”, as well as advanced IT solutions and targeted change management.

We also offer outstanding expertise in the area of advanced planning & scheduling (APS). These are software systems that support planners in solving planning problems in supply chain management (SCM) with the help of model-based approaches from the field of operations research. In contrast to the more transaction-oriented PPS or ERP systems, APS solutions offer the possibility of generating feasible or optimized plans on the basis of current planning data and restrictions. redpoint.teseon supports you in optimizing your existing planning system or successfully introducing a new one.

Get in touch with us! Our aim is to design and optimize your planning and control processes so that they are implemented and lived efficiently – together with you and in collaboration with customers, suppliers and network partners.